Thermal Expansion Testing

Thermal expansion occurs when the kinetic energy of a material’s molecules increases. With their increased movement, the molecules maintain a greater separation. The Coefficient of Thermal Expansion (CTE) is defined as the fractional increase in strain per unit change in temperature. It can be defined at a precise temperature or over a temperature range.

PMIC primarily uses Michelson Interferometry (ASTM E289) and Quartz Dilatometry (ASTM E228) to perform CTE measurements.

MICHELSON INTERFEROMETRY (ASTM E289)

The Michelson Interferometer is suitable for real-time displacement measurements of components with CTE values as low as 0.01 µm/(m·K). Components of arbitrary size and shape can be accommodated. Temperature can be accurately cycled between ≤ 30 K and 1273 K (-243 °C to 1000 °C). A component’s CTE can be measured in two or more directions simultaneously.

Precision optics, photodetectors, and interpolation techniques allow a length resolution to about a nanometer. Multi-directional strains can be determined simultaneously for composite components and structures.

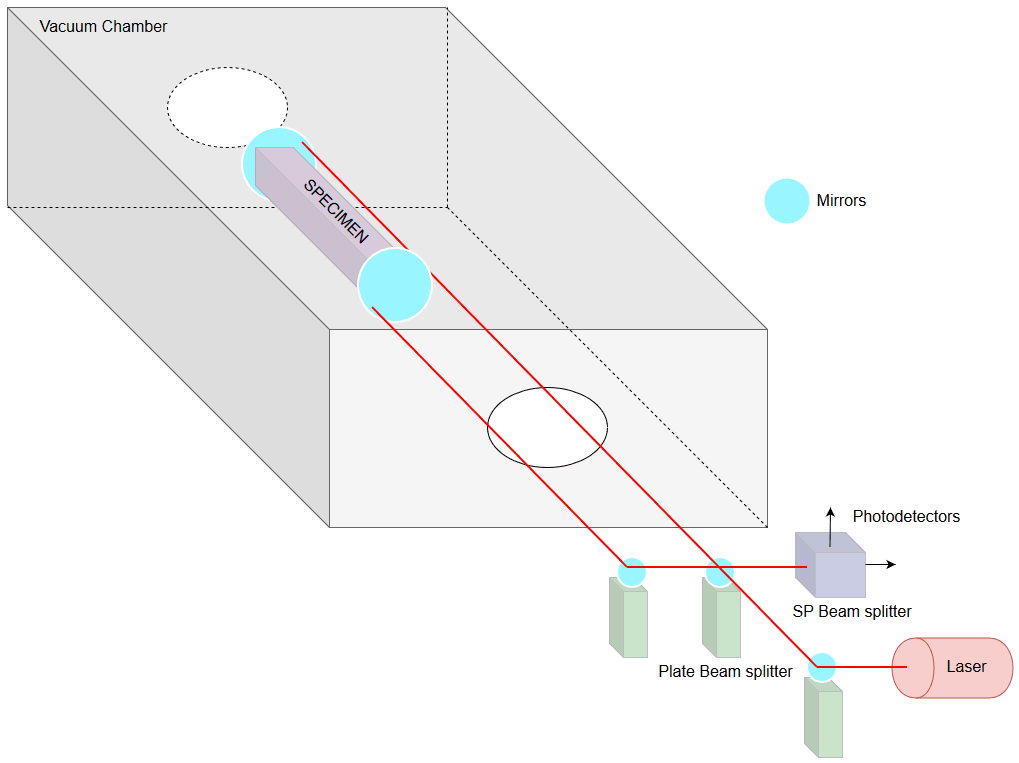

Figure 1 illustrates the basic features of a Michelson laser interferometer. A helium-neon (He-Ne) laser provides a stable single-frequency beam, which is then split by a beam splitter. One beam is reflected off the mirror and passes into the vacuum chamber where it is reflected off the front left specimen mirror. A second beam passes straight through the beam splitter and into the vacuum chamber where it is reflected off the rear right specimen mirror. These beams return along their respective paths and interfere, forming a fringe pattern. Each shift in the fringe pattern corresponds to a change in specimen length equal to one half the wavelength of the laser light (0.316 µm for a He-Ne laser). Photodetectors are used to sense shifts in the fringe pattern. The SP beam splitter separates the 0° and 90° components of the elliptically polarized fringe pattern light and directs them into the photodetectors.

The two photodetector signals are applied to the X-Y inputs of a data acquisition system to determine the direction of specimen strain as either expansion or contraction. One photodetector signal is recorded along with the output of temperature monitoring devices. The current temperature sensor value and photodetector output are continuously monitored and recorded. These data and the room temperature specimen length are used to produce a graph of microstrain versus specimen temperature. The slope of this graph is the coefficient of thermal expansion of the specimen.

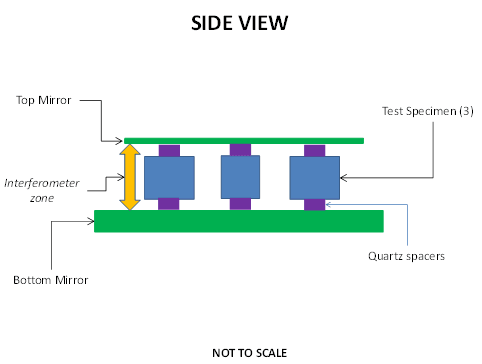

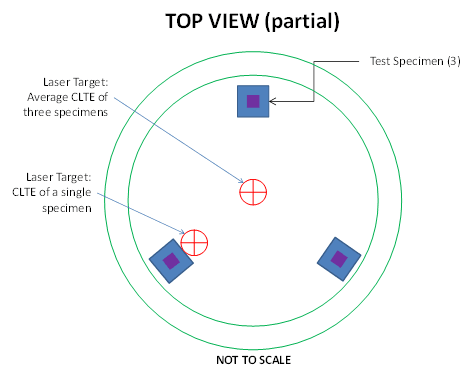

Z-direction measurements may be made using special setups, such as shown in Figures 2 and 3.

Materials with a higher CTE that do not require the high resolution of Michelson Interferometry are measured frequently using push-rod dilatometry. PMIC boasts higher-than-industry-standard resolution, expansive temperature ranges, and flexibility for specimen geometry in both its dilatometers and interferometers and will recommend whichever test method meets the customer’s needs best, based on system capability and system availability.

QUARTZ DILATOMETRY (ASTM E228)

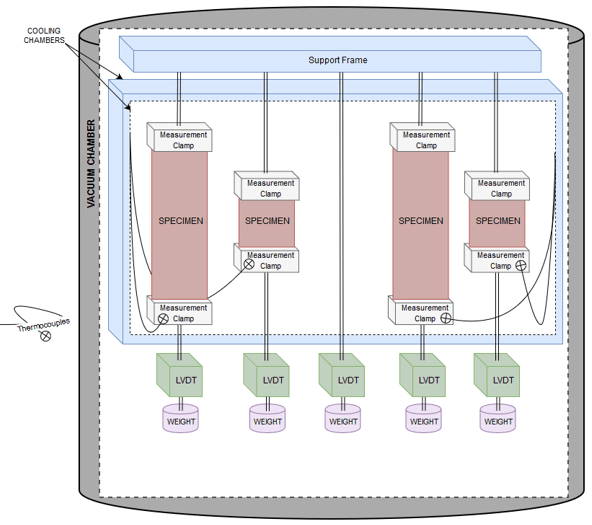

PMIC dilatometers utilize linear variable displacement transducers (LVDTs), which convert a change in measured length to voltage changes for processing by the data acquisition hardware and software (Figure 4).

PMIC push-rod dilatometry systems have been designed to reduce systemic errors from thermal gradients. They offer resolution as low as 0.050 µm/(m·K).

PMIC cycles specimens over the temperature range specified by the customer, continually recording temperature and change of length. Additional cycles may be requested. The mean coefficients of thermal expansion are calculated. Results are reported every 1 °C or 1 minute, whichever comes first.

PMIC achieves diametric testing of tubes and cylindrical specimens by placing three specimens radially between two quartz plates. The distance change of the two plates over the temperature range is measured.

HANGING DILATOMETRY

ASTM E228 has been modified by PMIC experts to handle flexible materials such as fabrics, thin laminates, metallic foils, and other non-rigid solids. PMIC uses a setup that measures both long and short specimens of the same material to reduce error induced from clamping the specimens (Figure 5).

THERMAL CYCLING and CTE

All PMIC thermal expansion techniques include real-time strain measurement and thermal cycling instrumentation. CTE changes with time and temperature may be caused by microcracking, phase changes, glass transition temperatures, moisture diffusion, plastic flow, etc. Such data permit accurate extrapolation to extended lifetime projections.

OPTICAL DIFFRACTION TECHNIQUES for CTE

Highly precise CTE measurements are made using various interferometric techniques. For temperatures above 1273 K (1000 °C) there are limitations, such as stability of reflecting surfaces. PMIC has developed a technique based on laser diffraction between sample edges and a refractory thin edge to measure CTE in almost any atmosphere and temperatures up to the specimen melting point.

Described at ITCC 27/ITES 15 Symposia, 2003: Knoxville, TN, Destech Publishers

VOLUMETRIC CTE

The total volume change of crystals, liquids, and many composites is usually measured by mercury-based systems over limited temperature ranges. PMIC has examined the specimen-induced displacements of organic and metallo-organic liquids in quartz capillaries over the temperature range of 200 K to 473 K (- 73 °C to 200 °C).

Described at ITCC 28/ITES 16, 2005: New Brunswick (www.thermalconductivity.org)

STRAIN GAGE CTE

Strain gages are ideal for finding localized strain in populated and unpopulated circuit boards and other odd-shaped materials, such as composite tubes. Due to the complex structure inherent in printed circuit boards (PCBs), measuring the bulk CTE does not always provide a clear picture of the strain at circuit concentration locations or at solder junctions. By using strain gages, PMIC can determine the strain at specific locations on the PCB. The circuits can then be mounted and re-tested to determine the effect mounting the circuits has on the bending of the PCB. Combining strain gages with bulk measurements from dilatometers provide a very clear and accurate strain representation of the PCBs. This method can also be done “in-situ” for an understanding of the PCB real-time behavior.

CTE ASTM Standards

| ASTM Standard | Name | System |

|---|---|---|

| E228 | Standard Test Method for Linear Thermal Expansion of Solid Materials With a Push-Rod Dilatometer | Dilatometer |

| E289 | Standard Test Method for Linear Thermal Expansion of Rigid Solids with Interferometry | Interferometer |

| E831 | Standard Test Method for Linear Thermal Expansion of Solid Materials by Thermomechanical Analysis | TMA |

| D696 | Standard Test Method for Coefficient of Linear Thermal Expansion of Plastics Between -30 °C and 30 °C with a Vitreous Silica Dilatometer | Dilatometer |

| C1300 | Standard Test Method for Linear Thermal Expansion of Glaze Frits and Ceramic Whiteware Materials by the Interferometric Method | Interferometer |